Global Wind Turbine Composites Market Overview

Wind Turbine Composites are being progressively used in the manufacture of wind turbine components. Superior mechanical properties, decreased operating expenditure, and a long lifespan has resulted in its increased use in the wind energy industry. Also, the lightweight property of composites enables the blades to rotate faster than other materials at the same wind speed. Moreover, reduced weight of turbine leads to less robust turbine requirements.

The major drivers are a shift towards renewable sources of energy in developed markets of Europe and North America. The increased lifespan and low operating expenditures have enabled it to be used in offshore wind energy installations as well. The major challenges are the high cost of composites and issue of reuse and recyclability of composite materials.

Wind Turbine Composites Market Size and Forecast – 2025 – 2032

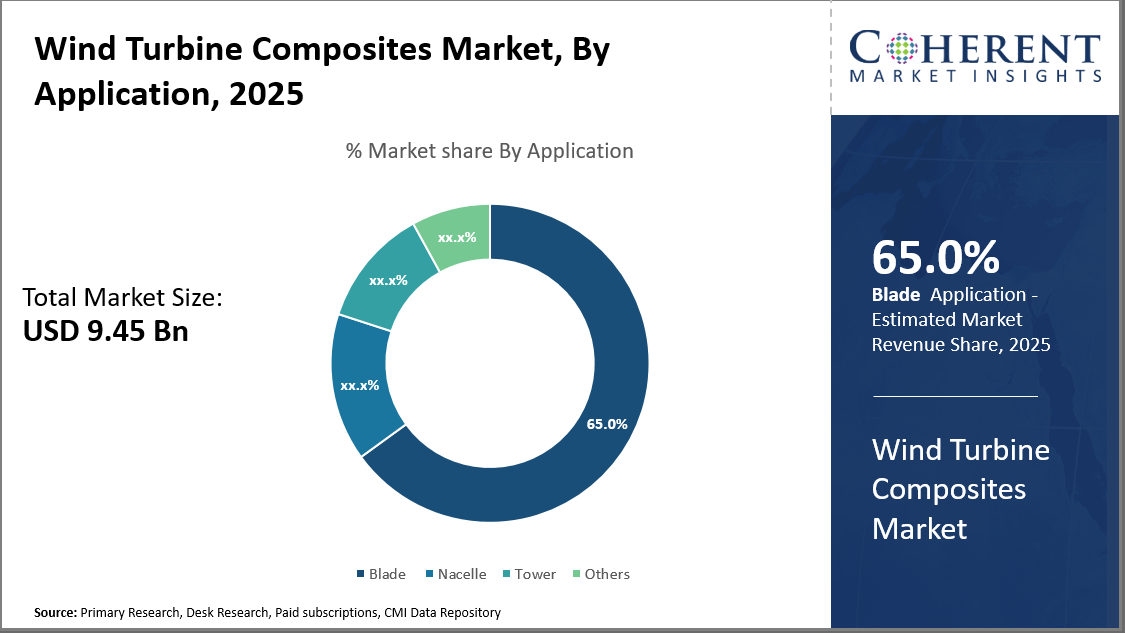

The Wind Turbine Composites Market size is estimated to be valued at USD 9.45 billion in 2025 and is expected to reach USD 16.28 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 8.2% from 2025 to 2032.

Key Takeaways

The blade application segment dominates the Wind Turbine Composites Market owing to sustained demand for longer, high-performance turbine blades, which accounted for approximately 65% of industry share backed by recent offshore wind projects.

The carbon fiber reinforced polymer (CFRP) segment is the fastest growing material Composite Material Type, driven by increasing use in larger offshore turbines where weight savings directly improve output and reliability.

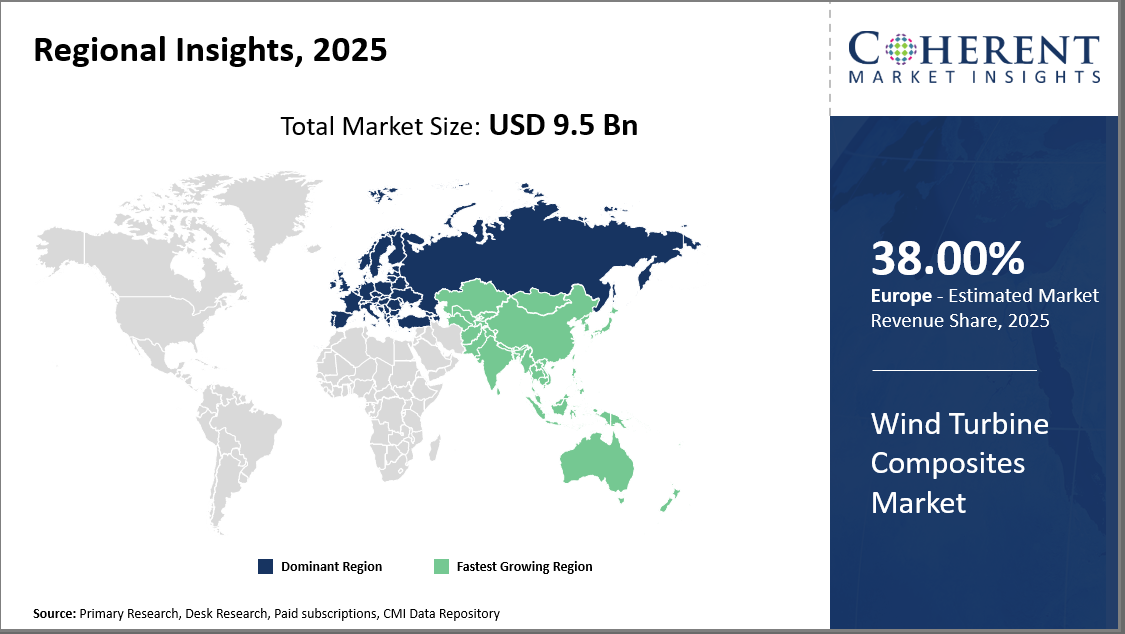

Among regions, Europe holds the commanding market share of approximately 38%, led by aggressive offshore wind capacity expansion and mature manufacturing hubs. Asia Pacific presents the highest CAGR, propelled by aggressive policy support and burgeoning installations in China and India.

North America maintains a solid market scope with steadily increasing investments in clean energy infrastructure and advanced composites manufacturing.

Wind Turbine Composites Market – Segmentation Analysis

To learn more about this report, Download Free Sample

Analysis of the Green and Bio Polyols Market, By Application

In terms of Application, the market is segmented into Blade, Nacelle, Tower, and Others, with Blade dominating a commanding 65% market share. This dominance is fueled by the integral role blades play in output generation and the necessity for advanced composites that provide lightweight durability to enable longer blade designs. The blade segment benefits from ongoing technological advancements in composite formulations and manufacturing processes to extend lifespan and performance.

Analysis of the Green and Bio Polyols Market, By Composite Material Type

Glass Fiber Reinforced Polymer (GFRP), Carbon Fiber Reinforced Polymer (CFRP), Aramid Fiber Composites, Hybrid Composites, and Others are the market segments based on the kind of composite material. Because of its balanced cost-to-performance ratio and track record of dependability in a variety of turbine applications, CFRP commands the largest market share of these, at 55%. Given the material's fatigue strength and resistance to corrosion, its widespread application in the production of blades bolsters its ongoing supremacy.

Analysis of the Green and Bio Polyols Market, By Turbine Type

In terms of Turbine Type, the market is segmented into Onshore, Offshore, and Floating types. Onshore turbines dominate the market share with 60%, benefiting from well-established wind infrastructure and steady demand for cost-effective turbine composites. This segment’s maturity ensures continuous development in composite standardization and supply chains.

Wind Turbine Composites Market Insights, By Geography

To learn more about this report, Download Free Sample

Europe Wind Turbine Composites Market Analysis and Trends

Europe remains the dominating region with approximately 38% market share, largely attributed to its extensive offshore wind installations supported by favorable regulatory frameworks, including the European Green Deal. Germany and Denmark, in particular, are pivotal players, with companies like Siemens Gamesa and LM Wind Power spearheading innovation.

Asia Pacific Wind Turbine Composites Market Analysis and Trends

The Asia Pacific region, on the other hand, is growing at the quickest rate, with a compound annual growth rate (CAGR) of nearly 9%. This is mostly due to China and India's vigorous expansion of renewable energy, as well as government subsidies that promote imports and domestic production. These nations' strong supply chains and infrastructure allow for quick market penetration and large inflows of income.

Wind Turbine Composites Market Outlook for Key Countries

Analysis of the United States Market for Wind Turbine Composites and Its Trends

Strategic investments in onshore and offshore wind energy, bolstered by federal programs like the Inflation Reduction Act (2022), which encourages the production of clean energy, define the US market. Supply chain resilience has increased as a result of major companies like Vestas and GE Renewable Energy expanding the nation's capacity to manufacture composite blades. The United States' offshore wind capacity expanded by more than 30% in 2024, which immediately raised demand for high-performance composites. Improved cost savings and quicker deployment timelines have been made possible by the cooperative ecosystem between manufacturers and raw material suppliers.

Analysis of the China Market for Wind Turbine Composites and Its Trends

The market for wind turbine composites in China is growing quickly thanks to aggressive renewable energy goals that seek to achieve carbon neutrality by 2060. By using more domestically made sophisticated composites, domestic companies like Goldwind and MingYang Smart Energy have reduced their reliance on imports. Adoption of specialist composite materials that can endure changing sea conditions has accelerated due to the growth of floating offshore wind farms along China's coast. Additionally, a 20% increase in composite material manufacturing capacity from 2023 to 2025 was made possible by the government's aggressive trade policies and subsidies, strengthening the nation's leading position in the regional market share.

Analyst Opinion

The expansion of offshore wind farms is a critical quantitative driver impacting the wind turbine composites market size. Offshore installations accounted for over 35% of new capacity additions globally in 2024, driven by Europe and Asia Pacific, significantly escalating demand for advanced composite materials tailored to withstand harsh marine environments. For instance, the European Offshore Wind Deployment Centre’s recent projects used high-modulus fiberglass composites, enhancing blade longevity by 25%.

Cost optimization through innovations in resin systems and manufacturing processes is influencing pricing dynamics and market revenue. In 2025, epoxy-based composites with improved cure cycles reduced production costs by up to 10%, fostering increased adoption. Market players investing in automation technologies have reported a 15% increase in production capacity efficiency, leading to expanded supply-side capabilities.

Demand-side market dynamics reflect diversified end-use cases beyond traditional electricity generation. Emerging sectors such as floating wind turbines and hybrid energy systems have necessitated composites with superior fatigue resistance. In Taiwan, the emergence of floating offshore wind farms in early 2024 showcased a 30% reduction in blade failure rates, evidencing the importance of niche composite applications.

Micro-indicators, such as regional raw material availability and export tariffs, are shaping market share distribution and global trade. In 2025, China’s resin export tariff adjustments improved their wind turbine composite exports by 18%, strengthening their market foothold in Latin America and Southeast Asia. Simultaneously, supply chain optimizations reduced lead times by 12% across North America, amplifying business growth opportunities.

Market Scope

| Report Coverage | Details | ||

|---|---|---|---|

| Base Year: | 2025 | Market Size in 2025: | USD 9.45 billion |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 8.2% | 2032 Value Projection: | USD 16.28 billion |

| Geographies covered: |

|

||

| Segments covered: |

|

||

| Companies covered: | Vestas Wind Systems, Siemens Gamesa Renewable Energy, GE Renewable Energy, TPI Composites, Mitsubishi Heavy Industries, Nordex SE, LM Wind Power, Suzlon Energy, Goldwind, MingYang Smart Energy | ||

| Growth Drivers: |

|

||

Uncover macros and micros vetted on 75+ parameters: Get instant access to report

Growth factors

The rapid increase in global offshore wind installations, legislated by governments targeting net zero carbon emissions by 2050, propels demand for lightweight, corrosion-resistant composites. Europe’s offshore wind capacity rose 22% in 2024, directly translating to market revenue growth.

Advances in composite technology, including nano-reinforced polymers and faster production methods, reduce material waste and improve blade performance, thus enhancing business growth. Innovations introduced in 2025 improved composite tensile strength by 18%, lowering failure rates.

Growing preference for larger turbines necessitates longer blades, which depend heavily on high-performance composites to maintain structural integrity. The blade application segment, holding a dominant market share, mirrors this demand upward trend globally.

Increased investment in emerging markets such as Asia Pacific, driven by supportive policies and infrastructure, boosts market size and forecast projections. China and India combined increased wind turbine composite imports by around 20% in 2024, reflecting expanding market scope.

Wind Turbine Composites Market Development

Market Trends

The Wind Turbine Composites Market is experiencing a notable shift toward multifunctional composites that integrate sensors for real-time blade health monitoring.

In 2024, several pilot projects in Germany used piezoelectric composites to anticipate fatigue damage, reducing maintenance costs by 15%.

Additionally, recycling and sustainability trends have emerged prominently, with recycled carbon fibre entering the supply chain and contributing to a 10% reduction in composite production carbon footprint.

Another emerging trend is the increased integration of digital manufacturing technologies such as automation and additive manufacturing, which have improved material utilization efficiency and reduced lead times significantly since 2023. These market shifts reflect a broader industry transformation focusing on sustainability and cost-efficiency.

Key Players

Vestas Wind Systems

Siemens Gamesa Renewable Energy

GE Renewable Energy

TPI Composites

Mitsubishi Heavy Industries

Nordex SE

Suzlon Energy

Goldwind

MingYang Smart Energy

Several leading companies have adopted vertical integration strategies to streamline composite material sourcing and blade manufacturing, resulting in cost leadership and improved market share. For example, Vestas’ strategic partnership with resin manufacturers in 2024 accelerated its composite blade delivery timeline by 20%. Siemens Gamesa enhanced market revenue by deploying digital twin technology for predictive maintenance, reducing downtime on offshore turbines by 15%, thereby strengthening its competitive positioning.

Prospects for the Wind Turbine Composites Market in the Future

The future outlook for the Wind Turbine Composites Market is very positive, driven by the increasing global focus on renewable energy and efforts to combat climate change.

As countries intensify their commitments to reduce carbon emissions, the deployment of wind energy projects is accelerating worldwide. This growth necessitates the use of advanced composite materials that provide strength, durability, and lightweight properties essential for longer and more efficient wind turbine blades and components.

Additionally, advancements in steam turbine technology complement renewable energy efforts by providing reliable and efficient power generation solutions across various renewable sources, enhancing grid stability and supporting the transition to a cleaner energy future.

Technological advancements in composite manufacturing and materials science are further enhancing performance, extending the lifespan of turbine parts, and reducing maintenance costs.

The expansion of both onshore and offshore wind farms, particularly in regions with strong government incentives and renewable energy targets, is a significant catalyst.

Additionally, innovation in recyclable and bio-based composites is addressing sustainability concerns and promoting circular economy principles.

Despite challenges such as the high production cost of composites and complex manufacturing processes, the market is expected to sustain robust growth due to increasing investments, scaling of turbine sizes, and global policy support for clean energy transitions.

The demand for wind turbine composites will continue to rise as wind energy plays an expanding role in the global energy mix, underpinning a promising long-term market trajectory.

Historical Analysis

In October 2018, Gurit acquired JSB Group a/S with the objective of enhancing their offerings associated with wind energy. The expertise of JSB group was helpful in offering material kits for wind turbine blades with manufacturing facilities in different regions of the world. JSB’s business operations were formulated as another business unit under Gurit with no changes in the brand name.

In March 2018, Toray Industries, Inc. acquired Koninklijke Ten Cate bv’s subsidiary “TenCate Advanced Composites Holding B.V.” This acquisition was helpful in gaining benefits from their expertise in the manufacturing of thermoplastics and thermoset prepreg. This acquisition helped in the expansion of technological and product capabilities of TORAY in combination with TenCate.

In 2016, Gamesa Corp supplied 94 wind turbines to DONG Energy for the Borselle 1 and 2 wind project in the Netherlands. The project boosted the wind turbines composites market in Europe.

Sources

Primary Research interviews:

Blade manufacturers (e.g., LM Wind Power, TPI Composites)

Renewable energy project developers

Wind farm operators and owners

Databases:

ScienceDirect

SpringerLink

Statista

Magazines:

CompositesWorld

Reinforced Plastics Magazine

Wind Systems Magazine

Journals:

Composites Part A: Applied Science and Manufacturing

Composites Part B: Engineering

Journal of Reinforced Plastics and Composites

Newspapers:

Financial Times (Renewables coverage)

The New York Times (Energy & Climate)

The Economic Times (Energy)

Associations:

American Wind Energy Association (AWEA) / American Clean Power Association (ACP)

European Wind Energy Association (WindEurope)

China Wind Energy Association (CWEA)

Share

Share

Missing comfort of reading report in your local language? Find your preferred language :

Transform your Strategy with Exclusive Trending Reports :

Frequently Asked Questions

Select a License Type

Joining thousands of companies around the world committed to making the Excellent Business Solutions.

View All Our Clients