Ultraviolet (UV) Curable Resins Market Size and Forecast – 2025 – 2032

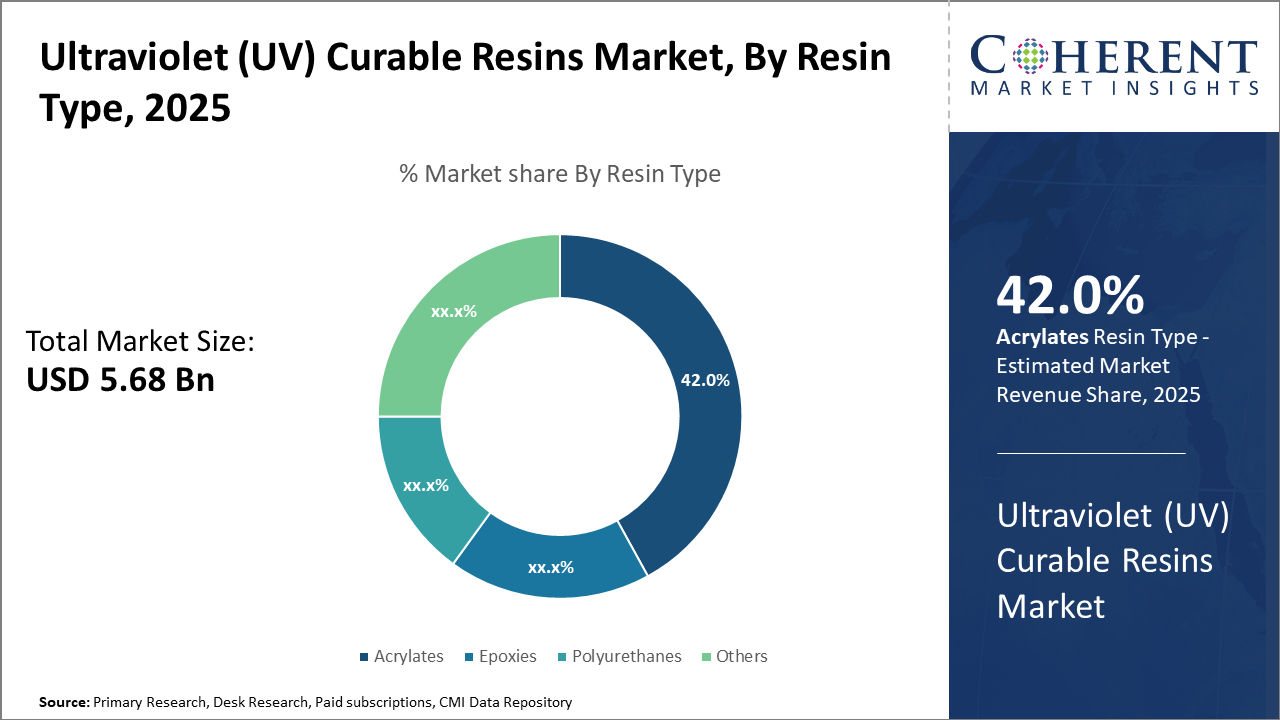

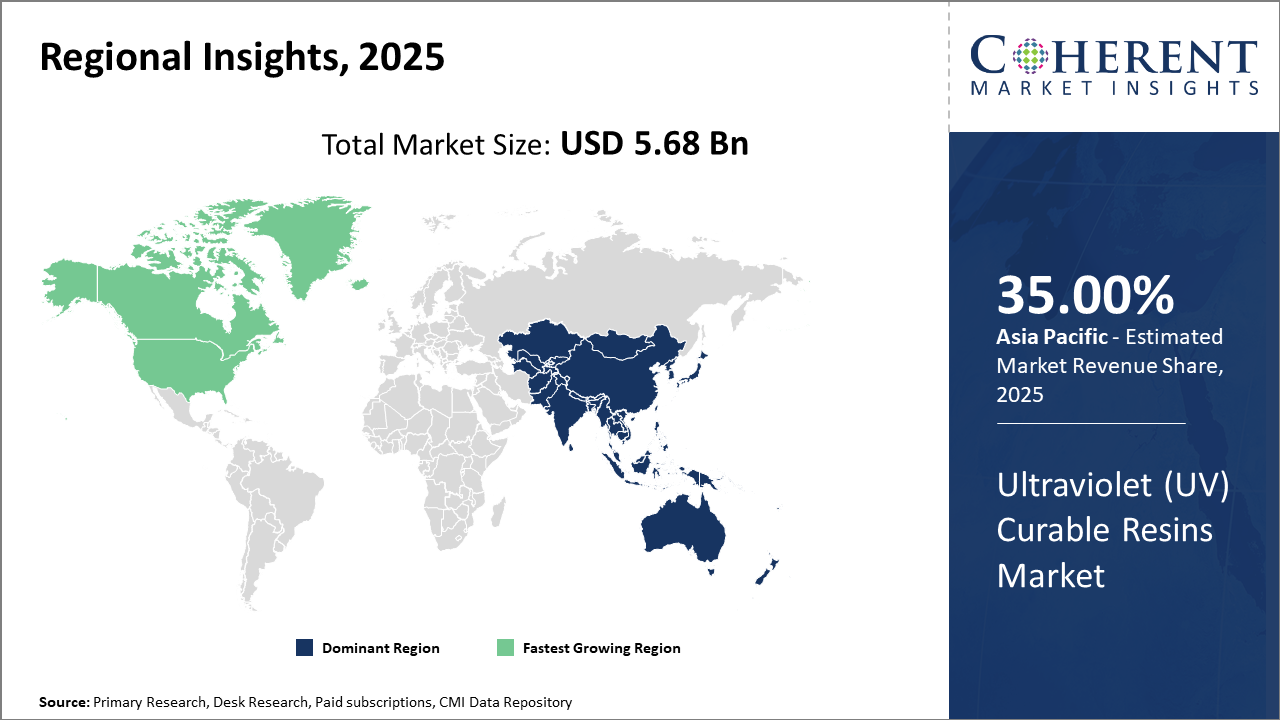

The Global Ultraviolet (UV) Curable Resins Market size is estimated to be valued at USD 5.68 billion in 2025 and is expected to reach USD 10.47 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 9.7% from 2025 to 2032.

Global Ultraviolet (UV) Curable Resins Market Overview

Ultraviolet (UV) curable resins are advanced polymeric formulations that harden rapidly when exposed to UV light, offering high-performance coatings, inks, and adhesives for industrial applications. These resins typically comprise oligomers, monomers, photoinitiators, and additives, providing instant curing without heat. The main advantages include fast processing time, low volatile organic compound (VOC) emissions, and superior adhesion and chemical resistance. Key product categories include acrylate-based, epoxy-based, and polyester-based UV resins, each tailored for specific uses in electronics, automotive, packaging, and 3D printing.

Key Takeaways

The acrylates segment remains the dominant resin type in the Ultraviolet (UV) Curable Resins market, holding 42% market share due to its versatility and superior curing properties.

Asia Pacific leads the regional market share, accounting for over 35% of total market revenue, driven by large-scale manufacturing ecosystems and supportive policies.

North America presents lucrative opportunities with a CAGR surpassing 10%, fueled by investments in R&D and the adoption of advanced automation in production lines.

Ultraviolet (UV) Curable Resins Market Segmentation Analysis

To learn more about this report, Download Free Sample

Ultraviolet (UV) Curable Resins Market Insights, By Resin Type

Acrylates dominate the market share with 42%. Its dominance arises from its rapid curing times, excellent adhesion, and compatibility with a wide range of substrates, becoming the go-to resin type in printing inks and packaging. Epoxies are the fastest-growing subsegment, driven by their superior chemical resistance and mechanical properties desirable in electronic encapsulants and industrial coatings. Polyurethanes, often chosen for flexibility and abrasion resistance, maintain steady demand in automotive and healthcare sectors.

Ultraviolet (UV) Curable Resins Market Insights, By Application

Electronics & Electrical stands out as the dominant application segment propelled by the growing need for miniaturized electronic components and rapid curing solutions to maintain production cycles. Packaging is among the fastest-growing segments due to sustainable packaging trends and government mandates on VOC reduction. Automotive applications focus on UV curable coatings for surface protection and aesthetics, while Medical & Dental applications are gaining traction with the rising use of biocompatible resins. Printing Inks leverage UV curing for high-speed digital printing, growing steadily alongside e-commerce packaging demands.

Ultraviolet (UV) Curable Resins Market Insights, By End-Use Industry

Consumer Goods occupy the largest market share. This is driven by extensive use of UV curable resins in packaging, household appliances, and electronics, supporting high revenue generation through volume consumption. Healthcare is witnessing the fastest growth, propelled by stringent regulatory standards for medical devices and dental prosthetics requiring advanced biocompatible UV curable resin formulations. The industrial sector remains consistent, using UV curable coatings for machine parts and tools, whereas automotive and construction industries continue leveraging these resins to meet durability and environmental regulations across various applications.

Ultraviolet (UV) Curable Resins Market Trends

The Ultraviolet (UV) Curable Resins market continues to capitalize on technological advancements that drive performance improvements and sustainability.

Notably, research into eco-friendly photoinitiators has led to a 16% reduction in VOC emissions in coatings utilized in packaging segments during 2024, a significant development aligning with global green manufacturing trends.

Furthermore, digital printing using UV curable inks has surged by over 25% since 2023, highlighting the growing application of these resins in innovative printing technologies, fostering new market expansion routes.

Ultraviolet (UV) Curable Resins Market Insights, By Geography

To learn more about this report, Download Free Sample

Asia Pacific Ultraviolet (UV) Curable Resins Market Analysis and Trends

In the Asia Pacific, the dominance in the Ultraviolet (UV) Curable Resins Market is attributed to robust manufacturing sectors, increased industrialization, and government incentives promoting clean technology adoption. Countries like China and India are key contributors, with China hosting major resin producers who supplied over 20% of the regional market volume in 2024. The presence of automotive hubs and electronics manufacturing clusters further cements the region’s hold on industry share.

North America Ultraviolet (UV) Curable Resins Market Analysis and Trends

Meanwhile, North America exhibits the fastest growth with a CAGR exceeding 10%, supported by advanced research ecosystems and early adoption of automation technologies in resin curing processes. The U.S. leads in innovations concerning photopolymer chemistry, pushing the boundaries of resin applications in healthcare and aerospace sectors. These factors collectively contribute to an accelerated market forecast within the region.

Ultraviolet (UV) Curable Resins Market Outlook for Key Countries

USA Ultraviolet (UV) Curable Resins Market Analysis and Trends

The USA's market plays a pivotal role, driven by significant investments in R&D and the presence of top-tier companies like Dow Inc. and Evonik Industries AG. In 2024, the U.S. accounted for nearly 28% of the North American market revenue, bolstered by the rapid adoption of UV curing technologies in automotive coatings and electronics manufacturing. Favorable regulatory frameworks emphasizing low VOC emissions have accelerated the transition toward UV curable resins, driving innovation and enhancing market share.

China Ultraviolet (UV) Curable Resins Market Analysis and Trends

China's market for UV curable resins is fueled by expansive industrial growth and government policies encouraging cleaner production technologies. Major players such as JSR Corporation and local manufacturers have ramped up production capacity by 20% in 2024 to meet rising domestic and export demand. The country's extensive packaging and electronics sectors continue to utilize UV curable resins at an increasing rate to comply with international environmental standards and remain competitive globally.

Analyst Opinion

The rise in industrial automation is a major supply-side indicator bolstering market growth. In 2024, automated UV curing systems increased production efficiency by over 18% in the electronics industry, directly impacting market revenue through improved resin consumption. Rapid curing times have become a decisive factor for manufacturers aiming to reduce lead times without compromising on quality or environmental compliance.

On the demand side, the shift towards lighter and flexible substrates in the automotive and packaging sectors has driven enhanced adoption of acrylate-based UV curable resins. For instance, the demand for flexible packaging materials using UV curable coatings grew by 23% from 2023 to 2024, indicating broader market adoption across emerging economies due to favorable import-export dynamics.

Market micro-indicators showcase a trend in specialty resin formulations designed for specific end-use applications, such as biocompatible coatings used in medical devices. In 2025, these niche applications accounted for approximately 12% of total UV curable resin market share, reflecting diversification and customized solutions fueling business growth.

Pricing trends demonstrate a moderate decline in raw material costs for photoinitiators and oligomers, attributed to increased global production capacities, especially in Asia Pacific, where resin production expanded by 15% in 2024. This enhanced supply chain stability has positively influenced market dynamics, ensuring competitive product pricing for end users and sustained market expansion.

Market Scope

| Report Coverage | Details | ||

|---|---|---|---|

| Base Year: | 2025 | Market Size in 2025: |

USD 5.68 billion |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 9.7% | 2032 Value Projection: |

USD 10.47 billion |

| Geographies covered: |

|

||

| Segments covered: |

|

||

| Companies covered: | BASF SE, Evonik Industries AG, DIC Corporation, Allnex, Covestro AG, JSR Corporation, Sartomer (Arkema), Dow Inc., Hexion Inc., BYK-Chemie GmbH, Mitsubishi Chemical Holdings Corporation, Henkel AG & Co. KGaA. | ||

| Growth Drivers: |

|

||

Uncover macros and micros vetted on 75+ parameters: Get instant access to report

Ultraviolet (UV) Curable Resins Market Growth Factors

The UV curable resins market growth is primarily driven by increasing awareness and adoption of sustainable coating technologies that reduce volatile organic compound (VOC) emissions. In 2024, the packaging industry, led by strict environmental regulation, saw a 20% increase in the adoption of UV coatings, highlighting market drivers centered around eco-conscious manufacturing. Rapid urbanization and infrastructure development, particularly in emerging economies, continue to amplify demand across the automotive and construction sectors for durable and aesthetic finishes utilizing UV-curable resins.

Additionally, advancements in photopolymer chemistry have enhanced product performance, broadening the industrial applications and stimulating market revenue growth. Economic factors such as trade incentives in Asia Pacific and North America have also contributed positively by enabling easier access to raw materials and reducing costs, fostering faster market expansion globally.

Ultraviolet (UV) Curable Resins Market Development

In May 2024, Allnex GmbH launched a high-performance waterborne UV-curable polyurethane acrylate specifically for wood-furniture coatings. This new resin is engineered for applications such as furniture topcoats and door finishes, enabling formulators to deliver higher durability, excellent substrate wetting, and low yellowing while operating in a waterborne UV-cure system. The launch reinforces Allnex’s growing position in the waterborne UV-curable resins market for industrial wood coatings.

In July 2023, BASF SE introduced three new high-performance UV acrylic hot-melt resins (acResin® ZeroPCF & LowPCF series) with a cradle-to-gate carbon footprint of zero or near-zero kg CO???e/kg, tailored for fast-curing applications. The products are designed for UV-curable adhesives, coatings, and specialty applications, offering identical performance to conventional resins but enhanced sustainability metrics (zero product carbon footprint in some cases).

Key Players

Leading Companies of the Market

BASF SE

Evonik Industries AG

DIC Corporation

Allnex

Covestro AG

JSR Corporation

Sartomer (Arkema)

Dow Inc.

Hexion Inc.

BYK-Chemie GmbH

Mitsubishi Chemical Holdings Corporation

Henkel AG & Co. KGaA.

Some market players have focused on strategic expansions and acquisitions to enhance product portfolios; for example, Allnex’s recent acquisition of a specialty resin producer in Europe boosted its market share by approximately 5% in 2024. Similarly, Evonik’s innovation in high-performance photoinitiators led to a 12% increase in sales within the North American region, showcasing market growth strategies rooted in R&D and geographic expansion.

Ultraviolet (UV) Curable Resins Market Future Outlook

The UV curable resins market’s near-term growth will be driven both by applications expansion and sustainability imperatives. Waterborne UV resins, LED-optimized photoinitiators, and formulations engineered for low migration and biocompatibility will gain share, supporting food-contact, medical, and consumer packaging uses. In additive manufacturing, resin innovation will expand into multi-material and functional resins (conductive, biocompatible, high-temperature resistant), unlocking new industrial uses.

Supply-chain localization for specialty monomers and vertical integration by major resin suppliers will stabilize pricing and responsiveness to OEM requirements. As production shifts toward smart factories and high-speed curing lines, UV resins tailored for LED engines and in-line quality control will be prioritized. Overall, the market will balance technical advancement with sustainability and regulatory compliance, producing steady growth across established and emerging industrial segments.

Ultraviolet (UV) Curable Resins Market Historical Analysis

The UV curable resins market originated as a specialized segment of coatings and inks, offering instant cure and high-throughput performance where thermal curing was impractical. Initially dominated by acrylate oligomers and monomers formulated for UV lamps, adoption broadened through the 1980s–2000s as photoinitiator chemistries improved and solvent-emission regulations made low-VOC systems attractive. The arrival of UV-LED curing hardware in the 2010s significantly reduced energy consumption and heat exposure to substrates, catalyzing adoption across heat-sensitive applications—packaging films, wood coatings, and electronics encapsulants. Global supply chains and raw-material availability cycles (acrylate monomers, photoinitiators) historically influenced price and R&D investment patterns, while environmental scrutiny prompted development of waterborne and solvent-free UV systems.

Sources

Primary Research Interviews:

Polymer Chemists

Coatings Engineers

R&D Scientists

Industrial Chemists

Databases:

EPA Chemicals Data

REACH Chemicals Database

Scopus

ScienceDirect

Magazines:

Coatings World

Paint & Coatings Industry

Chemical Engineering News

Adhesives & Sealants Industry

Journals:

Progress in Organic Coatings

Polymer Journal

Materials Today

Journal of Applied Polymer Science

Associations:

American Coatings Association (ACA)

European Coatings Association (ECCA)

ASTM International

ISO

Share

Share

About Author

Yash Doshi is a Senior Management Consultant. He has 12+ years of experience in conducting research and handling consulting projects across verticals in APAC, EMEA, and the Americas.

He brings strong acumen in helping chemical companies navigate complex challenges and identify growth opportunities. He has deep expertise across the chemicals value chain, including commodity, specialty and fine chemicals, plastics and polymers, and petrochemicals. Yash is a sought-after speaker at industry conferences and contributes to various publications on topics related commodity, specialty and fine chemicals, plastics and polymers, and petrochemicals.

Missing comfort of reading report in your local language? Find your preferred language :

Transform your Strategy with Exclusive Trending Reports :

Frequently Asked Questions

Select a License Type

Joining thousands of companies around the world committed to making the Excellent Business Solutions.

View All Our Clients