Refuse-Derived Fuel Market Size and Forecast – 2025 – 2032

The Global Refuse-Derived Fuel Market size is estimated to be valued at USD 8.7 billion in 2025 and is expected to reach USD 15.6 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 8.5% from 2025 to 2032.

Global Refuse-Derived Fuel Market Overview

Refuse-derived fuel is a processed fuel product made from municipal solid waste after removing recyclables and non-combustible materials. RDF typically consists of plastics, paper, textiles, and organic waste that are shredded, dried, and pelletized or fluff-processed for combustion. The product is used as an alternative fuel in cement kilns, power plants, and industrial boilers due to its calorific value and cost advantages over fossil fuels. RDF products are characterized by energy density, moisture content, ash content, and compliance with emission standards.

Key Takeaways

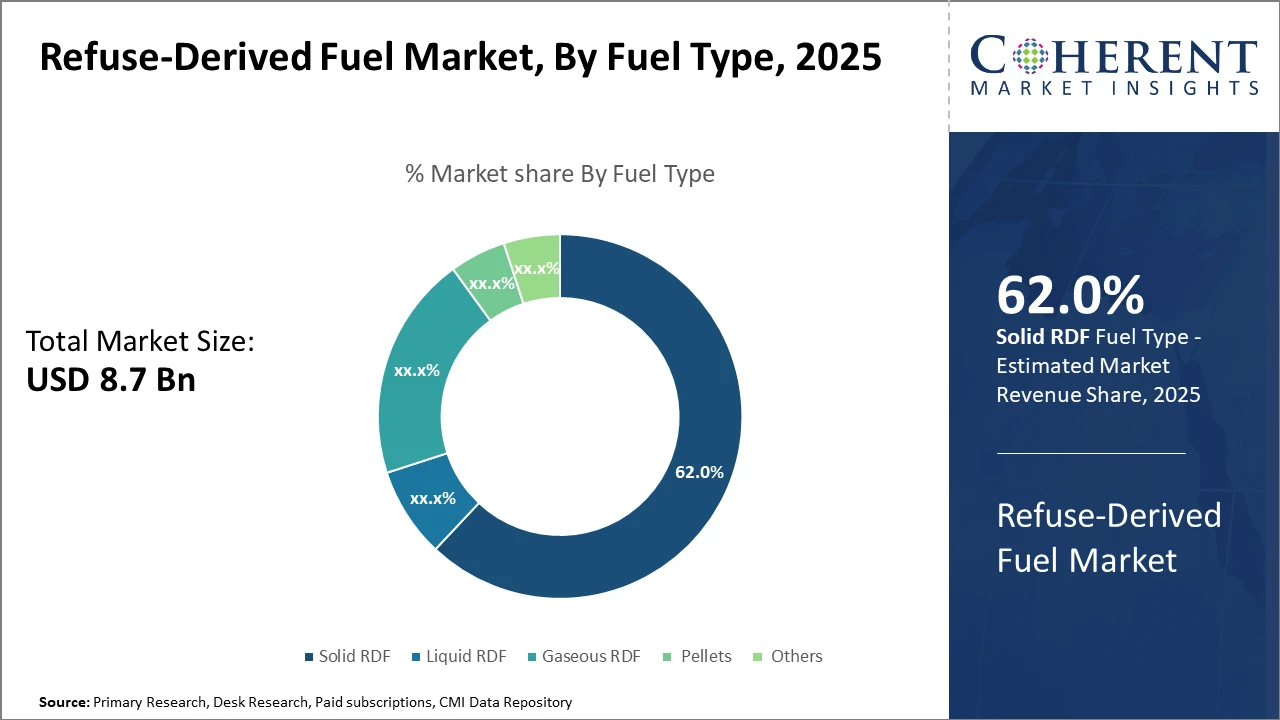

In the Fuel Type segment, Solid RDF accounts for over 60% of the market share due to its combustion efficiency and widespread application in energy-intensive industries.

The Cement Industry remains the largest application segment, contributing more than half of the market revenue, driven by cost-effective fuel substitution.

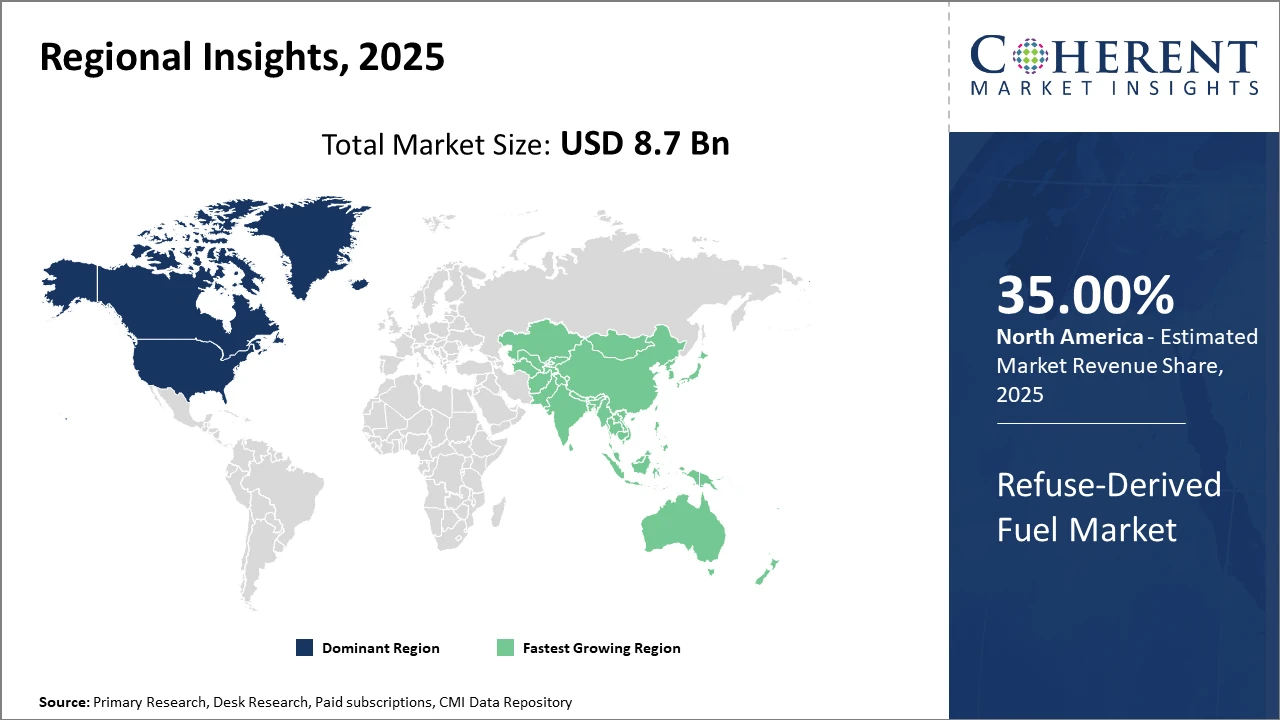

North America dominates the geographic market with a robust RDF infrastructure and supportive regulatory frameworks, accounting for 35% of global market revenue.

Asia Pacific is the fastest-growing region, with an anticipated CAGR exceeding 10%, fueled by increasing industrialization and government incentives for sustainable waste management.

Refuse-Derived Fuel Market Segmentation Analysis

To learn more about this report, Download Free Sample

Refuse-Derived Fuel Market Insights, By Fuel Type

Solid RDF dominates market share at 62%. The preference for Solid RDF arises from its higher calorific value, which suits high-demand applications such as cement kilns and power generation units. The segment’s expansion is bolstered by ongoing innovations in shredding and pelletizing processes, enhancing fuel uniformity. Liquid RDF is gaining traction due to its application in industrial boilers, benefiting from easy handling and combustion efficiency. Gaseous RDF and Pellets serve niche markets but are growing with technological enhancements in conversion methods, providing additional fuel options for diversified energy requirements.

Refuse-Derived Fuel Market Insights, By Application

The Cement Industry commands a 54% market share. The dominant share reflects the cement sector’s extensive adoption of RDF to reduce reliance on coal, benefiting from steady fuel supply agreements and cost-effectiveness. Power Generation is the fastest-growing application segment, propelled by waste-to-energy plants increasingly adopting RDF as a primary feedstock. Industrial Boilers also demonstrate growth opportunities through industries seeking environmental compliance while optimizing fuel costs. Residential Heating applications exist but remain relatively small owing to scaling challenges and fuel quality considerations.

Refuse-Derived Fuel Market Insights, By End-User Industry

Municipal Waste Management dominates the market revenue. This dominance is driven by structured municipal waste collection systems that supply consistent feedstock for RDF plants. Industrial Waste Management is growing rapidly, underpinned by stricter industrial waste disposal regulations and incentives for cleaner production. Commercial Waste Management, although a smaller subsegment, is gaining more attention due to rising waste volumes from the retail and hospitality sectors, contributing to overall market revenues. Others include specialized sectors where RDF usage remains exploratory but promising.

Refuse-Derived Fuel Market Trends

The Refuse-Derived Fuel market is witnessing accelerated digitization, with AI-powered sorting systems reducing contamination and enhancing fuel calorific values.

For example, a prominent RDF facility in Germany implemented AI technology in 2024, achieving a 20% increase in RDF quality.

Geographic expansion toward the Asia Pacific is notable, reflecting governmental drive for sustainable waste management in countries like India and China, which introduced subsidies for RDF plants in 2025.

The cement industry’s increasing use of RDF underscores a broader energy transition where industrial sectors mitigate carbon footprints by adopting alternative fuels.

This trend aligns with global carbon neutrality commitments gaining traction among market players.

Refuse-Derived Fuel Market Insights, By Geography

To learn more about this report, Download Free Sample

North America Refuse-Derived Fuel Market Analysis and Trends

In North America, the Refuse-Derived Fuel market dominance stems from an established waste collection ecosystem, stringent environmental regulations, and supportive policy frameworks promoting waste-to-energy adoption. The U.S. market, accounting for 35% of global market revenue in 2025, benefits from substantial infrastructure, demonstrated by the expansion of RDF-powered energy plants across several states, leading to improved market revenue and industry share year-on-year.

Asia Pacific Refuse-Derived Fuel Market Analysis and Trends

Meanwhile, Asia Pacific exhibits the fastest growth, with a CAGR surpassing 10%, driven by escalating industrial waste generation and governmental mandates favoring sustainable fuel sources. Countries such as India and China have initiated large-scale investments in RDF facilities, stimulating local market companies’ growth and broadening market scope. The improved waste management awareness and rising fossil fuel prices have reinforced the shift toward RDF utilization in this region.

Refuse-Derived Fuel Market Outlook for Key Countries

USA Refuse-Derived Fuel Market Analysis and Trends

The USA's RDF market is bolstered by federal and state-level incentives targeting renewable energy and waste minimization. In 2024, over 40 RDF production facilities were operational, with new capacity additions slated in key industrial states such as California and Texas. Leading domestic market players have actively pursued acquisitions to vertically integrate waste collection and RDF power generation. This approach, combined with strict emissions standards, has driven a steady market share increase and overall market revenue growth.

China Refuse-Derived Fuel Market Analysis and Trends

China's market has aggressively expanded RDF infrastructure amid the country’s commitment to a circular economy. The 2025 Waste-to-Energy policy revised emission thresholds, motivating cement manufacturers and power plants to augment RDF use. Major RDF producers have aligned with municipal bodies to secure steady feedstock supplies. These developments underpin China’s growing leadership in the Asia Pacific market, accelerated by investments from prominent regional market companies.

Analyst Opinion

Increasing adoption of waste-to-energy technologies is a critical demand-side driver shaping market size. For instance, in 2024, Europe witnessed a 12% uptick in RDF utilization in thermal power plants, reflecting a strategic shift towards cleaner energy sources amid tightening emissions norms.

Supply chain optimization and enhanced RDF production capacity are significant supply-side indicators. The establishment of new RDF processing plants in Asia Pacific increased production by 18% in the first half of 2025, supporting rising regional consumption.

Pricing trends indicate a steady rise, with RDF prices in North America increasing by approximately 7% YoY in 2024, influenced by higher demand from cement industries seeking cost-efficient fuel alternatives.

Diversification of end-use industries, including the expansion into industrial boilers and manufacturing sectors, is broadening the market dynamics. For example, a large steel plant in India incorporated RDF into its fuel mix in 2025, reducing conventional coal consumption by 22%, underscoring evolving market applications.

Market Scope

| Report Coverage | Details | ||

|---|---|---|---|

| Base Year: | 2025 | Market Size in 2025: | USD 8.7 billion |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 8.5% | 2032 Value Projection: | USD 15.6 billion |

| Geographies covered: |

|

||

| Segments covered: |

|

||

| Companies covered: | RenewEco Energy Ltd., GreenFuel Technologies, Enviro-Power Solutions, BioWaste Energy Corp., EarthCycle Industries, Global RDF Group, Waste2Energy Inc., CleanPath Energy, TerraFuel Systems, RecyclePower Holdings. | ||

| Growth Drivers: |

|

||

Uncover macros and micros vetted on 75+ parameters: Get instant access to report

Refuse-Derived Fuel Market Growth Factors

The Refuse-Derived Fuel market growth is primarily driven by increasing regulatory initiatives aimed at reducing landfill waste and greenhouse gas emissions, which have encouraged investments in waste-to-energy solutions. Governments in regions like Europe and the Asia Pacific have incentivized RDF production through subsidies and carbon trading schemes, accelerating market revenue. Technological advancements in RDF processing, such as automated sorting and contaminant removal, have enhanced fuel quality and demand in power generation and cement industries. Moreover, rising fossil fuel prices coupled with industrial sectors' growing environmental compliance expenditures, continue to drive sustained market growth.

Refuse-Derived Fuel Market Development

In 2025, a massive refuse-derived fuel (RDF) plant in Jakarta, Indonesia, began operations, positioning itself as the world’s largest RDF facility. The plant processes municipal solid waste into multiple fuel forms, supporting Indonesia’s waste-to-energy goals while significantly reducing landfill dependence and urban waste burden.

In 2024, the South Australia Environmental Protection Authority (EPA) developed and formalized regulatory standards for RDF production and combustion. These guidelines aim to ensure environmental safety, emissions control, and fuel quality consistency, enabling broader adoption of RDF across cement, power, and industrial sectors.

Key Players

Leading Companies of the Market

RenewEco Energy Ltd.

GreenFuel Technologies

BioWaste Energy Corp.

EarthCycle Industries

Global RDF Group

Waste2Energy Inc.

CleanPath Energy

TerraFuel Systems

RecyclePower Holdings

Key market companies have shifted toward vertical integration strategies, notably RenewEco Energy Ltd., which acquired a major waste management firm in 2024, enhancing its RDF production capacity by 30% and expanding downstream power generation assetsGreenFuel Technologies has successfully deployed advanced sorting and shredding technologies, leading to a 15% improvement in RDF quality and an associated rise in market share in 2025, especially in the European sector.

Refuse-Derived Fuel Market Future Outlook

The RDF market is expected to expand as waste management and energy generation become increasingly interconnected. Stricter landfill regulations, rising fossil fuel costs, and carbon reduction commitments will continue to support RDF adoption. Future developments will emphasize improved fuel quality, lower emissions, and integration with advanced waste-to-energy systems. Emerging economies are expected to increase RDF utilization as urbanization accelerates, while technological improvements in emissions control will enhance social acceptance and regulatory compliance.

Refuse-Derived Fuel Market Historical Analysis

The RDF market developed as municipalities sought sustainable solutions for managing increasing volumes of solid waste while reducing landfill dependency. Initially adopted in Europe, RDF gained traction as waste-to-energy regulations tightened and landfill taxes increased. Over the years, advancements in waste sorting, shredding, and processing technologies improved the calorific value and consistency of RDF products. Cement manufacturers and power producers increasingly adopted RDF as a partial replacement for coal, contributing to steady market growth. The market benefited from circular economy policies that emphasized resource recovery and waste valorization.

Sources

Primary Research Interviews:

Waste Management Operators

Cement Plant Managers

Energy Engineers

Municipal Authorities

RDF Processors

Databases:

World Bank Solid Waste Database

UN Environment Data

GlobalData Waste Reports

Magazines:

Waste Management World

Resource Recycling

BioEnergy Insight

Environmental Leader

Energy-from-Waste Magazine

Journals:

Waste Management Journal

Renewable & Sustainable Energy Reviews

Journal of Cleaner Production

Energy Policy

Resources Conservation & Recycling

Associations:

International Solid Waste Association (ISWA)

European Waste-to-Energy Association

Waste Management Association

CEWEP

Global Waste Association

Share

Share

Missing comfort of reading report in your local language? Find your preferred language :

Transform your Strategy with Exclusive Trending Reports :

Frequently Asked Questions

Select a License Type

Joining thousands of companies around the world committed to making the Excellent Business Solutions.

View All Our Clients