Reactive Hot Melt Adhesives Market Size and Forecast – 2025 – 2032

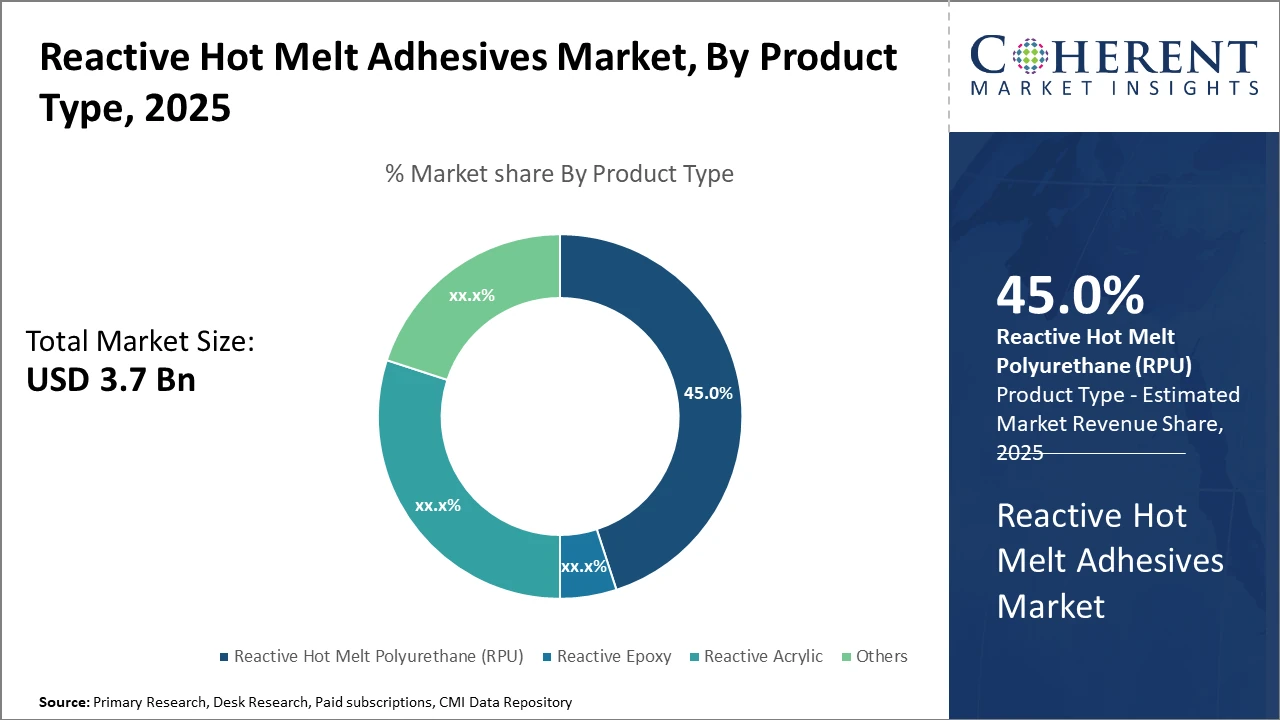

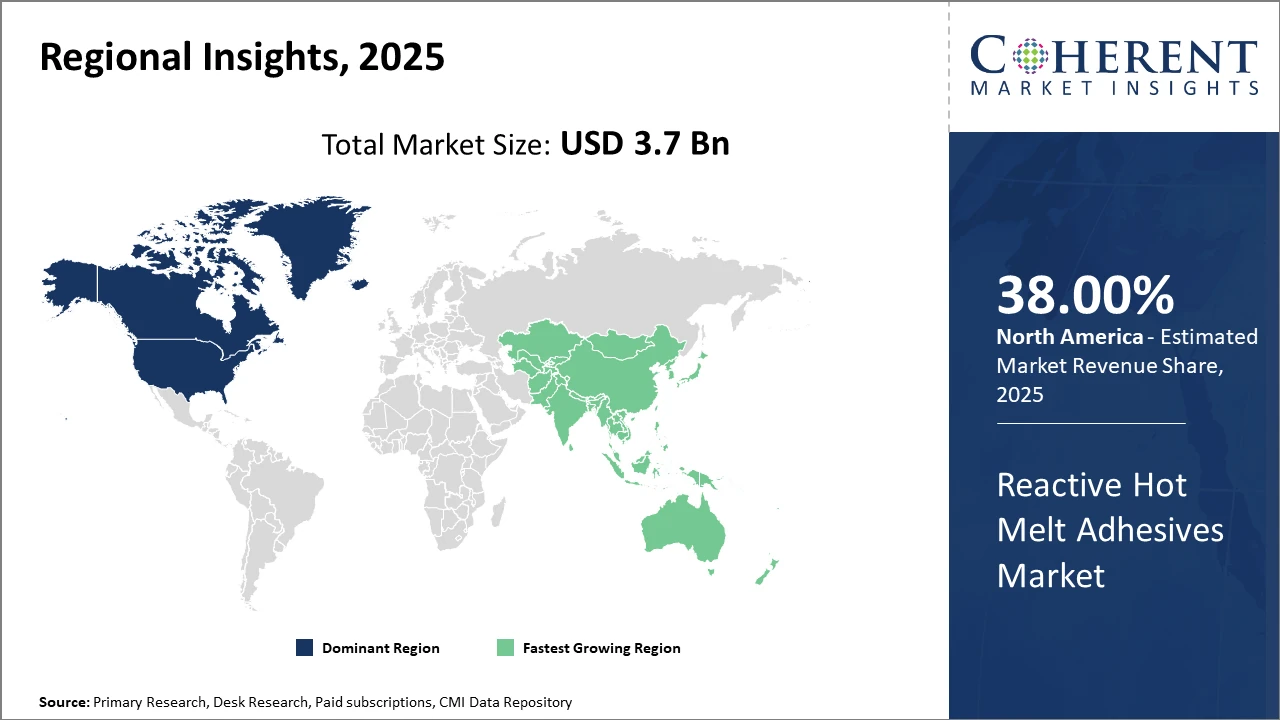

The Global Reactive Hot Melt Adhesives Market size is estimated to be valued at USD 3.7 billion in 2025 and is expected to reach USD 6.1 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 7.5% from 2025 to 2032.

Global Reactive Hot Melt Adhesives Market Overview

Reactive hot melt adhesives are thermosetting adhesive products that combine hot-melt processing with moisture-activated chemical curing. They are applied in molten form and subsequently react with ambient moisture to form strong, durable bonds. These adhesives offer high initial tack, excellent heat resistance, and long-term structural strength. Reactive hot melt adhesives are widely used in woodworking, automotive assembly, electronics, textiles, and packaging applications where high performance and durability are required.

Key Takeaways

The Reactive Hot Melt Polyurethane subsegment dominates product-type share, accounting for 45% of the market due to its superior thermal and mechanical properties.

Automotive applications maintain the largest segment share, driven by the shift to electric and hybrid vehicles requiring efficient bonding materials.

North America leads regional market share with approximately 38%, supported by strong automotive and aerospace sectors and government incentives encouraging green adhesives.

Asia Pacific is the fastest-growing region, exhibiting a CAGR exceeding 9%, fueled by rapid industrialization in China and India, alongside expanding electronics and packaging industries.

Reactive Hot Melt Adhesives Market Segmentation Analysis

To learn more about this report, Download Free Sample

Reactive Hot Melt Adhesives Market Insights, By Product Type

Reactive Hot Melt Polyurethane dominates the market share. RPU’s superior flexibility, thermal stability, and strong bonding capabilities make it the preferred choice in automotive and electronics applications, driving its extensive adoption. Reactive Epoxy is the fastest-growing subsegment, benefitting from its enhanced chemical resistance and mechanical strength, making it ideal for construction and aerospace sectors. Reactive Acrylic adhesives offer moderate performance and cost benefits, often utilized in packaging, while Reactive Silane caters to niche applications requiring exceptional moisture resistance. The ‘Others’ subsegment includes specialty formulations developed for specific industrial needs.

Reactive Hot Melt Adhesives Market Insights, By Application

Automotive and Transportation hold the dominant market share due to the increasing demand for lightweight bonding solutions that enhance fuel efficiency and meet stringent emission standards. Electronics and Electrical represent the fastest-growing application segment, propelled by miniaturization trends and the demand for flexible adhesives in devices like smartphones and wearable electronics. Packaging adhesives are steadily expanding, driven by requirements for quick setting and durable bonds in consumer goods. Footwear and Leather remain niche but stable segments with specialized adhesive needs. Construction adhesives support structural bonding but face some growth restraints due to traditional alternatives.

Reactive Hot Melt Adhesives Market Insights, By End-User Industry

Industrial Manufacturing holds the leading position, driven by diverse applications from assembly lines to packaging solutions. Consumer Goods is the fastest-growing subsegment due to increased demand for sustainable adhesives in packaging and household items. Meanwhile, the healthcare industry is gaining momentum, fueled by the need for medical-grade adhesives that comply with regulatory norms for safety and biocompatibility. Aerospace remains a vital but highly specialized sector requiring high-performance adhesives, whereas the ‘Others’ category encompasses emerging sectors such as renewable energy and electronics assembly, contributing gradually to revenue expansion.

Reactive Hot Melt Adhesives Market Trends

The market has witnessed accelerating innovation with a strong pivot towards sustainability and enhanced performance.

For instance, bio-based reactive hot melt adhesives gained prominence in 2024, aligning with global efforts to reduce carbon footprints, particularly across Europe, due to stringent environmental policies such as the EU Green Deal.

Additionally, the adoption of automation technologies and IoT integration within manufacturing processes has led to increased precision in adhesive applications and reduced waste, as highlighted by 2025 production data, wherein the implementation of digital adhesive dispensing systems reduced material losses by 12%.

Concurrently, specialized formulations targeting flexible electronics and medical devices have created new niches, contributing to market diversification.

Reactive Hot Melt Adhesives Market Insights, By Geography

To learn more about this report, Download Free Sample

North America Reactive Hot Melt Adhesives Market Analysis and Trends

In North America, the Reactive Hot Melt Adhesives market dominance stems from strong industrial sectors such as automotive, aerospace, and healthcare, collectively accounting for approximately 38% of the global market share. The United States leads due to its advanced manufacturing infrastructure and regulatory incentives promoting green adhesive technology. High adoption rates in automotive assembly lines and packaging further solidify this market position. Notable companies like Henkel and 3M have significantly contributed by launching innovative adhesive solutions tailored to the regional demand.

Asia Pacific Reactive Hot Melt Adhesives Market Analysis and Trends

Meanwhile, Asia Pacific exhibits the fastest growth, with a CAGR above 9%, driven by expanding electronics manufacturing hubs in China, India, and South Korea. Rapid urbanization and industrialization, coupled with government initiatives supporting high-tech manufacturing, underpin this expansion. The region benefits from investments in local adhesive production facilities, reducing dependency on imports and stimulating regional market revenue. Companies like Huntsman and Dow have enhanced their footprints here through partnerships and capacity expansions, capitalizing on the burgeoning market ecosystem.

Reactive Hot Melt Adhesives Market Outlook for Key Countries

USA Reactive Hot Melt Adhesives Market Analysis and Trends

The USA's Reactive Hot Melt Adhesives market remains a key global contributor, characterized by its innovation-driven landscape and robust end-user industries. The automotive sector alone increased adhesive consumption by nearly 15% in 2024, driven by the rise in electric vehicle manufacturing. Additionally, sustainability mandates from both federal and state-level policies have accelerated the adoption of bio-based adhesives. Major players such as Henkel and 3M lead with advanced R&D centers innovating adhesives with lower VOC emissions and increased durability, positively impacting market revenue and reinforcing the country’s industry share.

China Reactive Hot Melt Adhesives Market Analysis and Trends

China’s Reactive Hot Melt Adhesives market is rapidly emerging, propelled by the country’s expansive electronics manufacturing and packaging industries. In 2025, domestic production volume surged by 18%, partially due to government incentives aimed at localizing adhesive manufacturing and reducing import reliance. Companies have introduced tailored products to cater to the high-volume assembly lines in consumer electronics and automotive sectors. Huntsman’s strategic joint ventures in China have amplified supply capabilities, fueling the country’s growing market share and enabling it to capture a larger slice of the Asia Pacific reactive hot melt adhesives industry.

Analyst Opinion

The growing preference for reactive hot melt adhesives in automotive manufacturing highlights key demand-side dynamics. In 2024, automotive manufacturers increased their reactive hot melt adhesive consumption by approximately 12%, mainly due to the adhesives’ improved thermal resistance and structural bonding capabilities in lightweight vehicle assembly. This shift supports the sustained market growth and gradual increase in market share among industry players.

Supply-side factors also play a crucial role, with escalating production capacities in Asia Pacific pushing market revenue upward. For instance, in 2025, several chemical companies expanded their polymer synthesis facilities, enabling a 15% boost in adhesive output, correlating with rising export volumes to North America and Europe, thereby enhancing global market scope.

Market pricing dynamics reflect moderate stabilization, influenced by raw material cost fluctuations and evolving regulatory requirements. Despite raw material price surges of 8% in early 2025, manufacturers absorbed costs through optimized formulations, limiting final product price hikes to under 3%, which maintained demand momentum within key industrial segments, reinforcing business growth.

Market dynamics reveal a growing trend toward customized adhesives tailored for niche applications such as flexible electronics and medical devices. This nano-level segmentation is estimated to contribute to about 10% of total market revenue by 2026, underscoring strategic shifts among market players toward innovation-led expansion and diversified business portfolios.

Market Scope

| Report Coverage | Details | ||

|---|---|---|---|

| Base Year: | 2025 | Market Size in 2025: | USD 3.7 billion |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 7.5% | 2032 Value Projection: | USD 6.1 billion |

| Geographies covered: |

|

||

| Segments covered: |

|

||

| Companies covered: | Bostik SA, Ashland Inc., Dow Inc., Eastman Chemical Company, Evonik Industries AG, Lord Corporation, Soudal NV, Permabond LLC, The Adhesive Products Company, Panacol-Elosol GmbH. | ||

| Growth Drivers: |

|

||

Uncover macros and micros vetted on 75+ parameters: Get instant access to report

Reactive Hot Melt Adhesives Market Growth Factors

Key growth drivers in the market are multifaceted. Firstly, the automotive industry's shift toward lightweight materials demands efficient bonding solutions that reactive hot melt adhesives offer, demonstrated by a 14% surge in usage for electric vehicle manufacturing in 2024. Secondly, rising sustainability mandates have encouraged the adoption of eco-friendly reactive adhesives, especially in Europe, where regulations such as the EU Green Deal have fostered heightened market growth. Thirdly, increasing automation and miniaturization in electronics production are enlarging the adhesive market scope for high-performance bonding applications, supported by a 10% CAGR in the electronics segment adhesive consumption reported in 2025. Lastly, expanding packaging needs for fast-moving consumer goods are propelling demand, particularly with reactive hot melt adhesives enhancing packaging durability while enabling faster processing speeds, illustrated by a 7% increase in usage within the packaging sector in 2024.

Reactive Hot Melt Adhesives Market Development

In April 2024, VPF launched HM302, a bio-based, mineral oil–free rubber-based hot melt adhesive, developed to support more sustainable bonding solutions across packaging and industrial applications. The product addresses growing regulatory and customer demand for low-emission, renewable-content adhesives while maintaining strong adhesion performance and processing stability.

In 2023, Henkel introduced a new range of bio-based Technomelt reactive hot-melt adhesives (RHMAs) for packaging and automotive applications, reinforcing its sustainability-driven adhesive portfolio. In parallel, Henkel expanded its PUR adhesive production capacity in Shanghai to support rising Asia-Pacific demand, and earlier in 2022, collaborated with LyondellBasell to develop food-safe hot melt adhesives, strengthening compliance with global food-contact regulations and circular-economy goals.

Key Players

Leading Companies of the Market

Bostik SA

Ashland Inc.

Dow Inc.

Eastman Chemical Company

Evonik Industries AG

Lord Corporation

Soudal NV

Permabond LLC

The Adhesive Products Company

Panacol-Elosol GmbH

Leading market players are aggressively adopting product innovation and strategic partnerships to consolidate their industry share. For example, Henkel introduced a new bio-based RPU adhesive in early 2025, which claimed a 20% reduction in carbon footprint, gaining immediate traction in automotive OEM projects. Likewise, Huntsman has enhanced its production footprint in Asia through joint ventures, resulting in a 30% increase in revenue streams from the region in Q1 2025, illustrating successful market expansion strategies.

Reactive Hot Melt Adhesives Market Future Outlook

The reactive hot melt adhesives market is poised for continued growth driven by expanding demand in automotive lightweighting, high-performance packaging, and engineered composites. Future developments will focus on enhancing environmental performance, such as lower VOC emissions and incorporation of bio-based polymers, while maintaining or improving functional properties like heat resistance and bond durability. Digital manufacturing and process analytics will support more consistent quality control, especially in high-speed automated assembly applications. As industries demand stronger yet more sustainable bonding solutions, RHMAs that achieve faster cure times and broader substrate compatibility will find increasing relevance in advanced material systems.

Reactive Hot Melt Adhesives Market Historical Analysis

Reactive hot melt adhesives (RHMAs) emerged from earlier thermoplastic hot melts developed in the mid-20th century, which offered rapid setting times and strong adhesion but lacked high temperature and chemical resistance. By the 1980s and 1990s, chemical modifications incorporating moisture-curing groups (such as isocyanates) transformed hot melts into reactive systems capable of crosslinking after application. This innovation allowed RHMAs to bridge the performance gap between conventional thermoplastic adhesives and reactive liquid systems, making them valuable for demanding applications. Adoption grew in woodworking, automotive assembly, and packaging as formulators sought adhesives that combine fast setting with long-term durability. Over time, advances in polymer chemistry and processing technologies improved bond strength, heat tolerance, and compatibility with diverse substrates.

Sources

Primary Research Interviews:

Adhesive Formulators

Chemical Engineers

Manufacturing Plant Managers

Automotive OEM Engineers

Packaging Technologists

Databases:

UN Comtrade Adhesives

OECD Manufacturing Data

Magazines:

Adhesives & Sealants Industry

Chemical Week

Coatings World

Manufacturing Today

SpecialChem

Journals:

International Journal of Adhesion and Adhesives

Polymer Engineering Journal

Applied Polymer Science

Journal of Industrial Chemistry

Materials Science Journal

Newspapers:

Financial Times (Chemicals)

Reuters Chemicals

Bloomberg Markets

Economic Times

Business Standard

Associations:

Adhesive and Sealant Council

European Adhesive Tape Association

Society of Chemical Industry

Indian Chemical Council

American Chemical Society

Share

Share

About Author

Vidyesh Swar is a seasoned Consultant with a diverse background in market research and business consulting. With over 6 years of experience, Vidyesh has established a strong reputation for his proficiency in market estimations, supplier landscape analysis, and market share assessments for tailored research solution. Using his deep industry knowledge and analytical skills, he provides valuable insights and strategic recommendations, enabling clients to make informed decisions and navigate complex business landscapes.

Missing comfort of reading report in your local language? Find your preferred language :

Transform your Strategy with Exclusive Trending Reports :

Frequently Asked Questions

Select a License Type

Joining thousands of companies around the world committed to making the Excellent Business Solutions.

View All Our Clients