Chemical Indicator Inks Market Size and Forecast – 2025 – 2032

The Global Chemical Indicator Inks Market size is estimated to be valued at USD 1.15 billion in 2025 and is expected to reach USD 2.05 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 8.5% from 2025 to 2032.

Global Chemical Indicator Inks Market Overview

Chemical indicator inks are specialty formulations that undergo a visible color change upon exposure to predefined sterilization or processing conditions such as heat, steam, ethylene oxide, radiation, or specific chemicals. Containing reactive dyes, binders, solvents, and stabilizers, these inks are printed onto medical packaging, labels, and tapes to verify sterilization effectiveness. They are engineered for accuracy, substrate adhesion, non-toxicity, stability, and resistance to environmental interference, ensuring reliable process validation in healthcare and manufacturing settings.

Key Takeaways

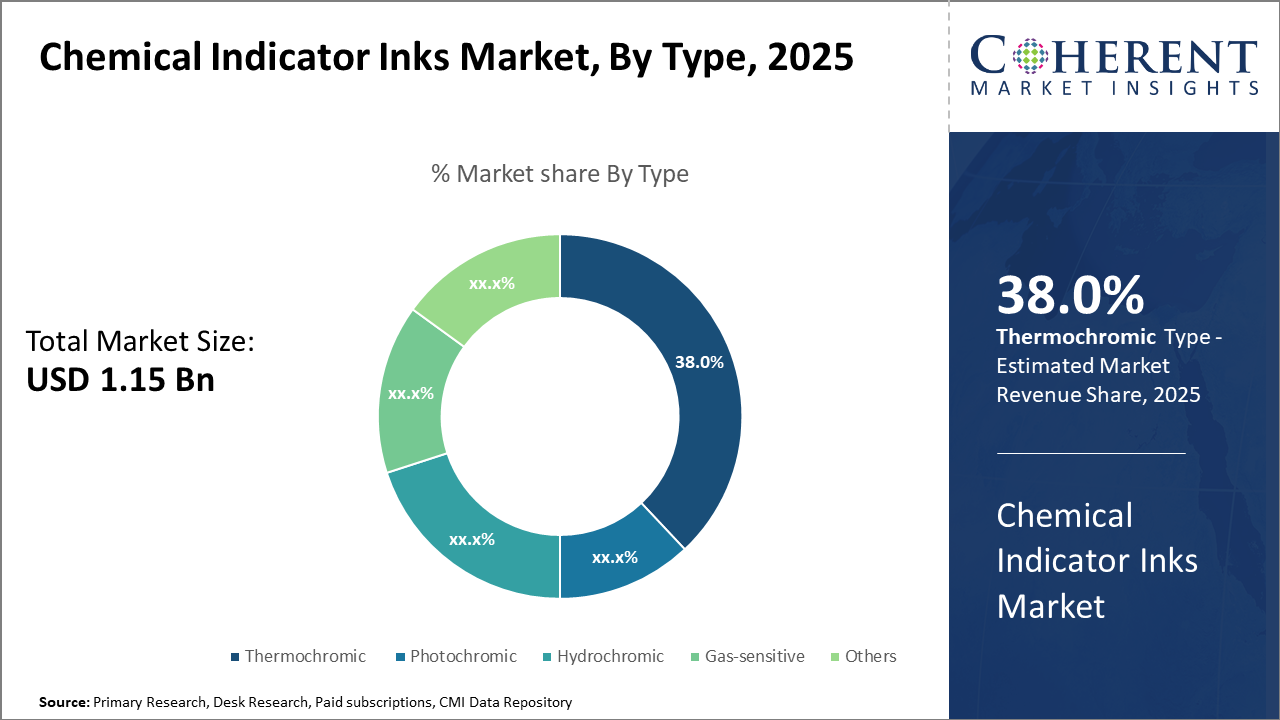

Thermochromic inks dominate with a 38% industry share due to their versatility and reliability in packaging and medical applications. Hydrophobic chemical indicator inks are rapidly gaining traction, driven by evolving use cases like humidity-sensitive food freshness indicators.

Packaging applications lead the Chemical Indicator Inks Market size, contributing 42% of market revenue, illustrating the sector’s role as a primary growth engine. The pharmaceutical end-user industry leverages indicator inks most intensively, mandated by regulatory environments requiring visual condition monitoring.

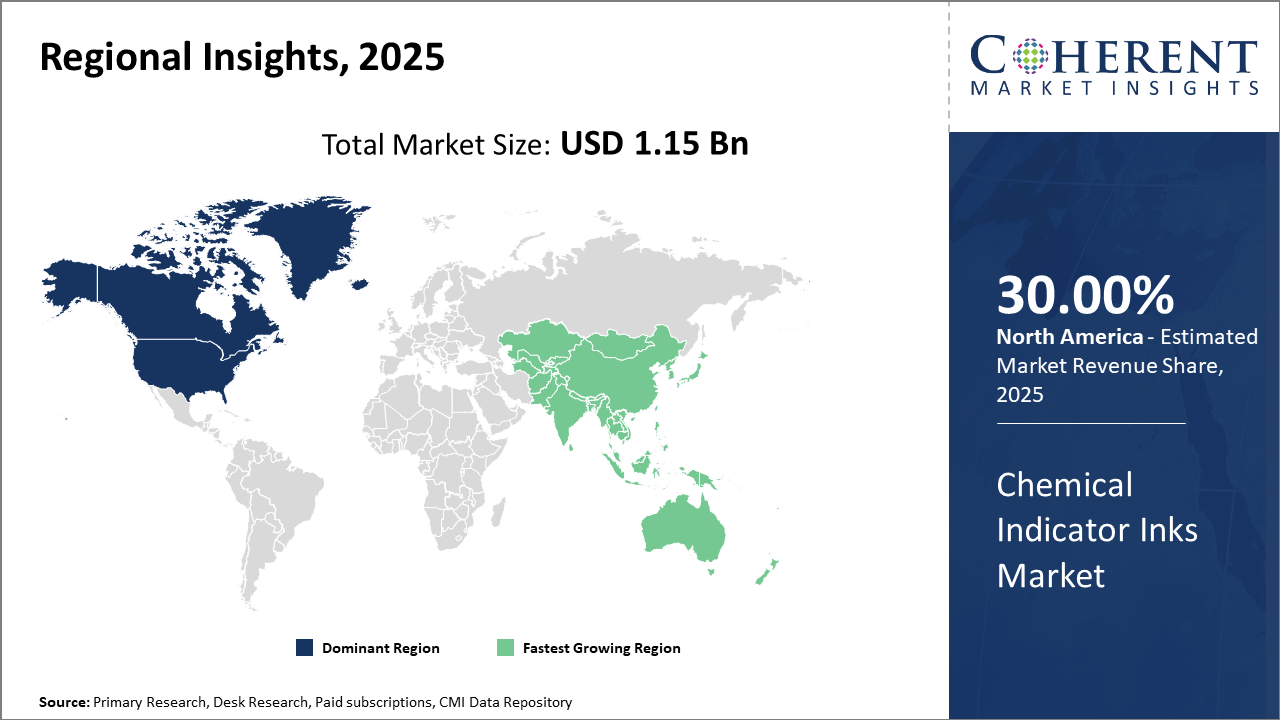

North America is the dominant regional market, accounting for over 30% market share, supported by a mature pharmaceutical industry and early adoption of smart packaging solutions.

Meanwhile, Asia Pacific exhibits the fastest CAGR, propelled by manufacturing expansion and rising exports, particularly from China and India.

Chemical Indicator Inks Market Segmentation Analysis

To learn more about this report, Download Free Sample

Chemical Indicator Inks Market Insights, By Type

Thermochromic dominates the market share due to its reliability in detecting temperature variations across packaging and medical devices, accounting for 38% market share. Their applications in pharmaceutical cold-chain monitoring underscore their dominance. Hydrochromic inks exhibit the fastest growth, increasingly adopted for humidity-sensitive food packaging, capturing emerging use cases related to freshness indicators. Photochromic inks find moderate application in security printing, while Gas-sensitive inks serve niche industrial monitoring purposes.

Chemical Indicator Inks Market Insights, By Application

Packaging is the dominant application, representing 42% of industry revenue, propelled by the growing need for tamper-proof and condition-monitoring solutions. Medical devices leverage chemical indicator inks for sterilization verification and product integrity, marking a rapidly expanding subsegment. Food safety applications utilize indicator inks for real-time freshness and spoilage detection, contributing to steady growth. Industrial processes benefit from chemical indicator inks in safety monitoring and quality control; however, their adoption is more specialized.

Chemical Indicator Inks Market Insights, By End-User Industry

Pharmaceuticals dominate the market share, driven by regulatory compliance for packaging and direct labeling, making it the most significant revenue contributor. Consumer goods manufacturers increasingly use indicator inks for authenticity and safety, with rapid adoption especially in personal care and food sectors, showing the highest growth trajectory among end-users. Automotive applications, while smaller, innovate with chemical inks for component monitoring and safety. Electronics adopt these inks in protective coatings and quality verification processes. The ‘Others’ include niche industries progressively integrating chemical indicator technologies as business growth opportunities.

Chemical Indicator Inks Market Trends

Recent market trends highlight a pivot towards sustainability and multifunctionality in chemical indicator inks.

One example is a 2024 initiative in Europe where several players launched biodegradable hydrochromic inks, reducing environmental impact while maintaining performance standards.

Another trend involves digital integration; smart packaging solutions embedded with indicator inks have streamlined quality assurance, showcasing a 20% improvement in end-user satisfaction reported by key pharmaceutical clients.

Additionally, the market is exploring active monitoring inks capable of signaling product tampering in real-time, a feature increasingly sought in high-value electronics and food sectors.

Chemical Indicator Inks Market Insights, By Geography

To learn more about this report, Download Free Sample

North America Chemical Indicator Inks Market Analysis and Trends

In North America, the Chemical Indicator Inks market leads globally with over 30% market share, mainly driven by the United States' robust pharmaceutical and packaging sectors. Stringent FDA regulations requiring transparent product monitoring enhance adoption rates. The region's well-established infrastructure and trends toward smart packaging further fortify its dominant position. Major companies such as Sun Chemical and Sensient Technologies maintain leading roles, investing seriously in innovation to retain competitive edges.

Asia Pacific Chemical Indicator Inks Market Analysis and Trends

Meanwhile, the Asia Pacific region registers the fastest growth with a CAGR surpassing 10% in recent years. This expansion is bolstered by rising manufacturing output in China and India, increasing exports, and government initiatives supporting smart manufacturing ecosystems. The burgeoning consumer base and rising demand for advanced packaging solutions fuel the upward momentum. Local market players and multinational entrants are actively establishing manufacturing facilities and partnerships to capture this high-growth potential.

Chemical Indicator Inks Market Outlook for Key Countries

USA Chemical Indicator Inks Market Analysis and Trends

The United States remains a critical hub, driven by advanced pharmaceutical research and stringent regulatory frameworks necessitating precise chemical indicator solutions. Industry players have launched specialized ink lines targeting tamper-evident packaging, supporting growth in healthcare packaging segments by approximately 18% in 2024 alone. Additionally, the U.S. sees active investments in digital printing integration, enhancing the growth prospects of Chemical Indicator Inks market revenue.

China Chemical Indicator Inks Market Analysis and Trends

China’s Chemical Indicator Inks market benefits from a large-scale manufacturing sector and increased export activities to end-user countries worldwide. Local companies have significantly increased production capacity while embracing sustainable ink technologies, contributing to a strong rise in market share. Regulatory push toward safer packaging and product monitoring continues to boost demand, with market players collaborating on innovation hubs fostering rapid product development and application expansion.

Analyst Opinion

Increasing production capacity in Asia Pacific is a key driver, especially as manufacturers ramp up output to meet the burgeoning demand from packaging and healthcare sectors. For instance, multiple facilities in China reported a 15% capacity increase in 2024, directly influencing the overall market size.

Pricing dynamics have shown a steady upward trend, reflecting the rising cost of raw materials such as pigments and substrates necessary for chemical indicators. In 2025, price indices for chemical dye inputs surged by approximately 7%, impacting market revenue but also prompting innovation in cost-effective ink formulations.

Demand-side indicators highlight the expanding use of chemical indicator inks in the pharmaceutical packaging segment, with adoption growing by 22% YOY in North America. This is driven by heightened regulatory requirements for tamper-evident and authenticity labeling.

Market micro-indicators reveal an increased preference for eco-friendly and water-based chemical indicator inks, following regulatory restraints on solvent-based variants. This shift aligns with sustainable industry trends observed across Europe, where green chemistry initiatives enhanced market share of eco-conscious inks to 35% in 2024.

Market Scope

| Report Coverage | Details | ||

|---|---|---|---|

| Base Year: | 2025 | Market Size in 2025: |

USD 1.15 billion |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 8.5% | 2032 Value Projection: |

USD 2.05 billion |

| Geographies covered: |

|

||

| Segments covered: |

|

||

| Companies covered: | Sun Chemical, Sensient Technologies Corporation, H. B. Fuller Company, Flint Group, DIC Corporation, Toyo Ink Group, Clariant AG, Sakata INX, Chromatic Technologies Inc., MITSUBISHI PAPER MILLS LTD. | ||

| Growth Drivers: |

|

||

Uncover macros and micros vetted on 75+ parameters: Get instant access to report

Chemical Indicator Inks Market Growth Factors

The surge in demand for smart packaging solutions is a predominant growth driver, fueling the adoption of chemical indicator inks in global packaging industries. The pharmaceutical sector's stringent regulations requiring real-time monitoring of product conditions have intensified market consumption of indicator inks embedded in medical packaging. Additionally, increasing consumer awareness regarding product safety and authenticity promotes wider use of these inks in the food and beverage sectors. Furthermore, advancements in ink formulations allowing multiple color transitions under varying conditions are stimulating market growth by broadening application scopes. Industry reports from 2024 reaffirm that digital integration with chemical indicators in smart devices could boost market dynamics by enabling enhanced traceability and quality assurance in logistics.

Chemical Indicator Inks Market Development

In October 2023, Mesa Laboratories, Inc. acquired GKE-GmbH’s fumigation indicators business and its testing lab, SAL GmbH, adding specialized sterilization and decontamination monitoring products to its portfolio. The move broadens Mesa’s global presence and strengthens its offering for pharmaceutical, medical device, and laboratory quality assurance.

In 2023, True Colors Limited signed a distribution agreement with Spain-based ITACA to supply its digital inks and chemical solutions in India, ensuring better product compatibility and streamlined access for domestic manufacturers. The partnership enhances True Colors’ market reach and supports the growing demand for advanced digital printing technologies.

Key Players

Leading Companies of the Market

Sun Chemical

Sensient Technologies Corporation

H. B. Fuller Company

Flint Group

DIC Corporation

Toyo Ink Group

Sakata INX

Chromatic Technologies Inc.

MITSUBISHI PAPER MILLS LTD.

Several leading companies have adopted growth strategies such as strategic collaborations and enhanced R&D investments to advance their product portfolios. For example, Sun Chemical’s partnership with pharmaceutical packaging firms in 2024 resulted in a 12% increase in their market share by introducing advanced thermochromic inks. Similarly, Sensient Technologies accelerated its expansion into the Asia Pacific through localized manufacturing units, improving delivery timelines and reducing costs, positively impacting regional market revenue.

Chemical Indicator Inks Market Future Outlook

In the coming years, rising healthcare infrastructure investment, stricter regulatory compliance, and increasing surgical procedure volumes will sustain demand. Innovation will focus on eco-friendly formulations, low-VOC inks, digital traceability, sensor-based monitoring, and integration into automated packaging and sterilization workflows. As global medical device manufacturing expands—especially in Asia—indicator inks will play a growing role in export certification and sterilization documentation. Opportunities also lie in food packaging, industrial safety labeling, and anti-counterfeit authentication technologies.

Chemical Indicator Inks Market Historical Analysis

The chemical indicator inks market emerged with the institutionalization of sterilization protocols in hospitals, pharmaceutical production, and medical device packaging. Initially limited to basic heat-sensitive inks, the industry expanded significantly with the growth of disposable medical products, centralized sterilization units, and regulatory quality assurance requirements. Over time, formulation technology evolved to support multi-parameter indicators, improved color contrast, substrate compatibility, and better resistance to environmental interference, cementing its role in process validation and patient safety.

Sources

Primary Research Interviews:

Hospital Sterilization Managers

Medical Device Packaging Engineers

Quality Assurance Specialists

Industrial Printing Technologists

Databases:

FDA Medical Device Database

Magazines:

Healthcare Packaging

Infection Control Today

Label & Narrow Web Magazine

Medical Device & Diagnostic Industry (MD+DI)

Journals:

Journal of Sterile Services

Journal of Medical Devices

Packaging Technology and Science

American Journal of Infection Control

Newspapers:

The Washington Post (Health)

The Hindu (Healthcare Industry)

The Wall Street Journal (Medical Devices)

Financial Express (Manufacturing)

Associations:

Association for the Advancement of Medical Instrumentation (AAMI)

ASTM International

International Organization for Standardization (ISO)

Healthcare Sterile Processing Association (HSPA)

Share

Share

About Author

Yash Doshi is a Senior Management Consultant. He has 12+ years of experience in conducting research and handling consulting projects across verticals in APAC, EMEA, and the Americas.

He brings strong acumen in helping chemical companies navigate complex challenges and identify growth opportunities. He has deep expertise across the chemicals value chain, including commodity, specialty and fine chemicals, plastics and polymers, and petrochemicals. Yash is a sought-after speaker at industry conferences and contributes to various publications on topics related commodity, specialty and fine chemicals, plastics and polymers, and petrochemicals.

Missing comfort of reading report in your local language? Find your preferred language :

Transform your Strategy with Exclusive Trending Reports :

Frequently Asked Questions

Select a License Type

Joining thousands of companies around the world committed to making the Excellent Business Solutions.

View All Our Clients