With the current rate of progress in science and technology in our modern world, rapid manufacturing technologies, especially 3D printing technology, has become an essential tool for automobile manufacturing; now playing a key role in improving production efficiency, realizing high customization, and reducing production costs, to name a few.

However, in order to best gauge the value of utilizing 3D printing technology, more in-depth research needs to be done. This research can be further strengthened by delving into its basic application process, its specific applications in the field of automotive machinery manufacturing, and the prospects for development in the future.

In the future, with the continuous advancement of technology, rapid manufacturing technology will further promote the development of the automotive industry, achieve a higher level of customization and green manufacturing, and meet the market demand for environmental protection and efficient production.

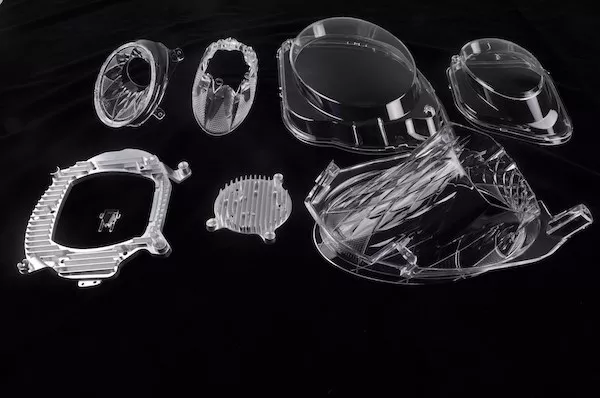

Innovative Automotive Exterior Modeling

These days, 3D printing technology can now be used to produce personalized automotive exterior parts, such as lights, wheels, doors, and so on. Car owners can have the thrill of customizing the appearance of their cars according to their own preferences, while designers can use 3D printing technology to quickly create appearance prototype and structural models. They can then and test and optimize the features to satisfy the car owners to have the car of their dreams. This can also dramatically shorten the vehicle design cycle and improve design efficiency.

In addition, engineers can use 3D printing to select lightweight materials for car body parts, thereby reducing the vehicle’s weight and thus improving fuel efficiency. In addition, 3D printing technology can be used to create automotive exterior appearance prototype made from biomaterials, solving the problem of disposing of discarded cars. So, it’s great for the environment, too.

Enabling Automotive Robotic Design

3D printing technology is an exciting development of the sophistication of computer technology, and through the deep integration of the two, it can further realize automotive robot design. With the help of computer programming and artificial intelligence technology, personalized virtual reality solutions can be generated to achieve the design of automotive robots, so that the car can better meet the requirements of users, rather than being limited to the field of transport tool development.

For example, designers can now enter key information into a computer according to the design requirements and then use 3D printing technology to obtain an automotive robot that meets the technical requirements. This design not only meets the practicality requirements but also enhances the car’s technology, taking it to the next level and into the future.

Think of a cockpit design; a space capsule model can be created and equipped with seat headrests to enhance overall comfort and make it ergonomic for the specific purpose of flight. In cars, the back seat can incorporate a folding design concept to meet the unique needs of the driver. So, in the near future, automotive robots can provide users with a smarter ride, more comfortable ride, and more exciting driving experience.

Enhancement of Intelligent Vehicle Interior Design

With the rapid development of the automotive industry, the functional classification of automobiles has become more and more diversified, and a variety of models have been launched one after another, such as commercial vehicles, sports cars, off-road vehicles, and more. Not only that, the interior and functional design of all kinds of models are constantly updated, optimized, and improved. However, when it comes to the actual driving process, some models are yet to meet the user's individual needs. Based on these developments, in the future, we can see things beginning with the optimization of automotive interiors, the use of 3D printing technology to strengthen those designs interiors, and further launching more intelligent automotive interiors, so as to enhance the technological intelligence of the car.

Green Printing Material Manufacturing

Being quite different from traditional manufacturing technology and manufacturing processes, 3D printing technology utilizes a combination of digital models and three-dimensional entity rapid manufacturing. This enhances the accuracy of the manufacturing process using advanced, intelligent, precise characteristics, and that’s just the beginning.

In terms of material application, 3D printing technology is primarily realized through layer-by-layer printing and superimposed printing, and the material is a lot more selective. In terms of the automotive machinery manufacturing field, plastics, (as raw materials for automotive parts production) are the most commonly used materials. As we well know, plastics contribute to environmental pollution, therefore, in the context of sustainable development, when applying rapid manufacturing technologies like 3D printing to manufacture automotive parts, green printing materials can be taken as a much-welcome positive development for the future. Printing materials will hopefully be able to meet the green production guidelines, and green-use requirements, making for a more sustainable future for the planet.

Printing Car Parts Using Binder Jet Sand

Tesla has reportedly been exploring a 3D printing technique called ‘binder jetting’ to develop sand patterns for making large castings. In this process, large and complex parts such as the underside of the car body are cast into one whole metal casting. This particular use of 3D printing in the design of the casting will require a lot less cost and time, while also being able to design more complex castings.

In Binder Jet Tesla's 3D-printed sand, SuperCast’ (a large car part printer), industrial sand is laid on a sand bed, with liquid adhesive being selectively applied layer by layer based on a digital design to create a complete 3D shape.

This is similar to ‘selective laser sintering’ (SLS), except that a binder is used instead of melting to turn the powder into a solid shape. Each print takes just a few hours, meaning that prototypes can be adapted as many times as needed, and the entire design validation cycle costs as little as 3 percent of traditional methods! It also cuts the overall development time from a year to two or three months.

Another important benefit of 3D printing that Tesla plans to take advantage of is the possibility of sand casting more complex models because large structural components often have cavities to reduce weight and improve crash resistance.

Summary

The use of 3D printing rapid manufacturing technology to manufacture automotive end-products in place of traditional components, directly on the body, chassis, engine, and interior and exterior trim, allows for product innovation, performance enhancement, and some pretty exciting personalization.

By far the greatest value of 3D printing is to enhance the value of the product, with the effect being truly remarkable in complex parts, innovative products (topology optimization), and personalization. It’s time for designers in the automotive field to get up to speed and explore the application value of 3D printing technology, and pay more attention to its advantages and the edge it can give in terms of the early stages of design, (or even product planning stage), the introduction of this kind of thinking, 3D printing manufacturing modes to design products, and breakthroughs in traditional concepts of the limitations. All of this will lead to product performance that will bring greater joy to car owners, as well as advancements and substantial revenue increases for the automotive industry.

Disclaimer: This post was provided by a guest contributor. Coherent Market Insights does not endorse any products or services mentioned unless explicitly stated.